Study with the several resources on Docsity

Earn points by helping other students or get them with a premium plan

Prepare for your exams

Study with the several resources on Docsity

Earn points to download

Earn points by helping other students or get them with a premium plan

Community

Ask the community for help and clear up your study doubts

Discover the best universities in your country according to Docsity users

Free resources

Download our free guides on studying techniques, anxiety management strategies, and thesis advice from Docsity tutors

Some concept of Turbomachinery Aerodynamics are Axial Flow Compressors, Axial Turbine Design Considerations, Blade Performance, Engine Performance Significantly, Flows Through Axial Compresso. Main points of this lecture are: Centrifugal Compressors, Impellers, Diffuser, Vanes, Inlet Guide, Volute, Design Possibilities, Double-Sided Impeller, Multi-Staged Compressor, Velocity

Typology: Slides

1 / 22

This page cannot be seen from the preview

Don't miss anything!

1

Centrifugal Compressors

Design of Centrifugal Compressor elements – Impellers, Vanes etc.

Other Design Possibilities: a) Double-sided impeller : b) Multi-staged compressor

Other important issues to be designed

Slip factor

In a real compressor relative velocity vector V 2 is at angle β 2 because of non-radial exit from the impeller tip as the real viscous flow detaches near the tip from the impeller vane (trailing) surface

0.63.π / N σ = 1 - 1 -. tanβ

s

0.63.π σ = 1- N

Stanitz formula ,

which, for a radial vane,

φ 2 r^2 2

U_**

2

r2 2 σ 1 ( / )cosβ

1 (V /U )

σ 1 ( / )

N

N

π

π

= −

−

= − 2

2 tanβ

cosβ

Wisner’s definition

Stodola Definition

Where & N= no. of blades

No dependence on backsweep

β 2 <-45^0 ; N>

β 2 >-45^0 ; N>

00 < β 2 <-60^0

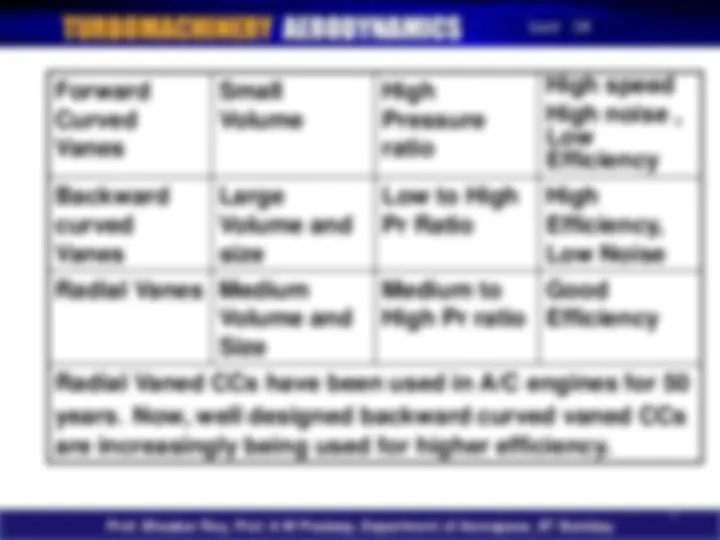

Forward Curved Vanes

Small Volume

High Pressure ratio

High speed High noise , Low Efficiency

Backward curved Vanes

Large Volume and size

Low to High Pr Ratio

High Efficiency, Low Noise

Radial Vanes Medium Volume and Size

Medium to High Pr ratio

Good Efficiency

Radial Vaned CCs have been used in A/C engines for 50

years. Now, well designed backward curved vaned CCs are increasingly being used for higher efficiency.

At the compr. entry face

a 1 1

C tanβ = U

U 1 = ω.reye where r (^) eye varies from the root to the tip of the eye

Thus for a high speed compressor (or large sized) β 1 shall vary hugely from root to tip of the eye.

Under off-design operations,

i =r β - β** (^1 1) r

High positive incidence i (≥ +5^0 ) may precipitate early flow separation inside the impeller vane passage, even near the eye, specially if high diffusion ( i.e. high adverse pressure gradient ) is being attempted inside the impeller vanes.

To be decided by designer

At the exit plane of the impeller, the exiting flow deviates from the trailing edge and lag behind in rotational mode. This is often referred to as the lag or deviation angle.

av 2 2

δ = β - β

which is an average at the passage exit, and β 2 * is the impeller vane exit angle set by design

Diffusion Limit :

An upper limit of realistic diffusion limit V 2 /V 1 ≈ 0. In rotating diffuser V 2 /V 1 < 0. In Impeller design, ρ 1 A 1 / ρ 2 A 2 > 2.

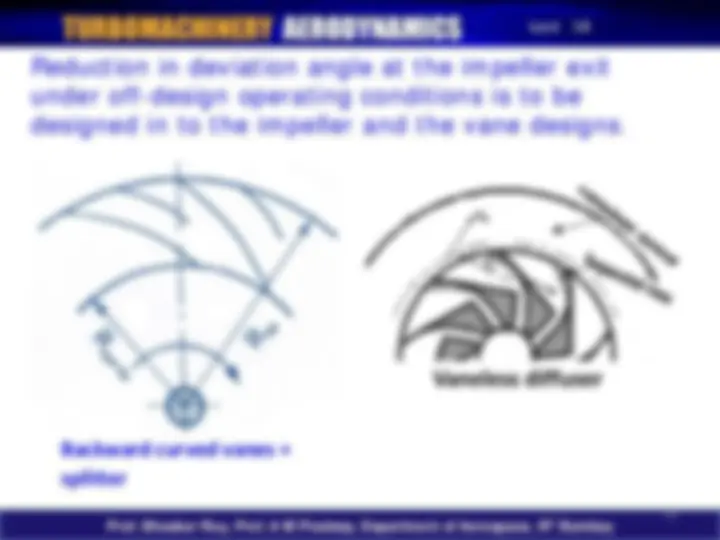

Backward curved vanes + splitter

Reduction in deviation angle at the impeller exit under off-design operating conditions is to be designed in to the impeller and the vane designs.

Vaneless diffuser

.( - 1). ) 0C = 1 +^ 0c

γ η γ γ - π

= (^)

2 03 s 2 1 w 2 01 01

pΨ. (σ. U - U .C p a

The general relationship for Compressor Pressure ratio is given by

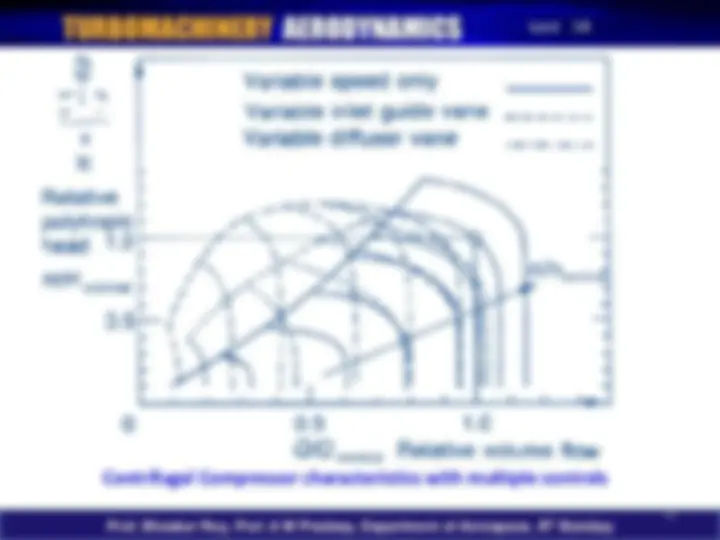

With Speed Control and Flow Control

Stall and Surge control

Losses : Ideal and Real Characteristics