Study with the several resources on Docsity

Earn points by helping other students or get them with a premium plan

Prepare for your exams

Study with the several resources on Docsity

Earn points to download

Earn points by helping other students or get them with a premium plan

Community

Ask the community for help and clear up your study doubts

Discover the best universities in your country according to Docsity users

Free resources

Download our free guides on studying techniques, anxiety management strategies, and thesis advice from Docsity tutors

Conclusions relative to the manufacture and heat treatment of duralumin ... L. M. Cohn, Changes in the physical properties of aliuninimi and its alloys, ...

Typology: Study notes

1 / 50

This page cannot be seen from the preview

Don't miss anything!

CONTENTS (^) Page

II. GDmposition and preparation of alloys (^273) III. Heat treatment and aging (^273)

IV. Miscellaneous^ tests^293

V. Mechanism^ of^ hardening^ during^ aging^ after^ rapid^ cooling^299

I. INTRODUCTION

The remarkable phenomena exhibited by the aluminum alloy

known as duralumin were discovered during the years 1 903-1 911

by A. Wilm^' ^^ and have been described by him and others. ^'^ ^'^ ^'^ ^

The unusual feature of this alloy is the fact, as was shown by

Wilm, that it can be hardened quite appreciably by quenching

from temperattu-es below its melting^ point followed by aging at

material (^) to stand at these temperatures. The hardness (^) is not produced by the quenching alone, but increases during the (^) period

8, p. 225; 1911.

272 Scientific Papers^ of the Bureau (^) of Standards [Voi.

of aging, which (^) may be (^) from one to three days. Cohn (see notes

3 and^ 5, p.^ 271) gives^ data^ showing^ the^ increase^ of^ hardness^ of

450° C. Upon annealing the alloy so hardened by aging, (^) it is

The composition of this alloy usually varies within the following limits:

Copper (^) 3-4-

Manganese (^) o — o. (^7) Aluminum (^) Balance

Silicon (as impurities)^ o. 3 — o. 6

condition.

This alloy has been produced for some years commercially and

is in demand for the fabrication of parts for which both lightness

and (^) strength are required, such as for aircraft. (^) Its tensile strength

will average 50 000 to 60 000 pounds per square inch after appro-

priate heat treatment, such as that described by Wilm.

With the pmpose of ascertaining whether the heat treatment

described by him actually developed the best mechanical proper-

temperatin-e, aging^ temperatiu-e,^ etc.,^ upon^ these^ properties^ and,

chemical composition upon them.

E. Blough^ had^ already^ called^ the^ attention^ of^ one^ of^ the^ authors

to the fact that the amount of hardening produced by heat treat-

ment was influenced quite markedly by the temperature from

which the material was quenched, a most interesting fact which

was not brought out by Wilm's published investigations, which

mentioned merely the effect of aging after quenching from one

An explanation was sought also for the mechanism of hardening

during aging of this alloy, and additional data were obtained

bearing upon this phase of the matter.

The experiments^ here^ described^ were^ carried^ out^ partly^ in^ the

laboratories of^ the^ Bureau^ of^ Standards^ and^ partly^ in^ cooperation

274 Scientific^ Papers^ of the^ Bureau^ of Standards^ [Vol.^ IS

electric furnace,^ quenching^ in^ water,^ and^ aging^ at room or other

temperatures for^ different^ periods.^ The^ results of these tests are

and of Heat-treated Aluminum-Copper-Magnesium Alloys

Number

As rolled

Sclero-

fying er

Tensile strength

tion in 2 inches

After annealing at 422" C

Sclero- scope

fying hammer

Tensile strength

tion in 2 inches

Lbs./in. 49 000 48 400 48 600 49 600 25 800 23 600 23 600 34 900 35 700 34 000 38 400 38 600 (^37 ) 35 900 37 500 37 700 35 300 38 500 38 100 44 200 45 500 45 300 38 100 38 100 41 200 43 200 41 200 44 800 44 600 47 500 56 700 52 900 58 400 38 900 38 600

Lbs./in. 33 000 33 100 32 700

Merica, WcdtenbergA (^) Heat Treatment (^) of Duralumin (^275)

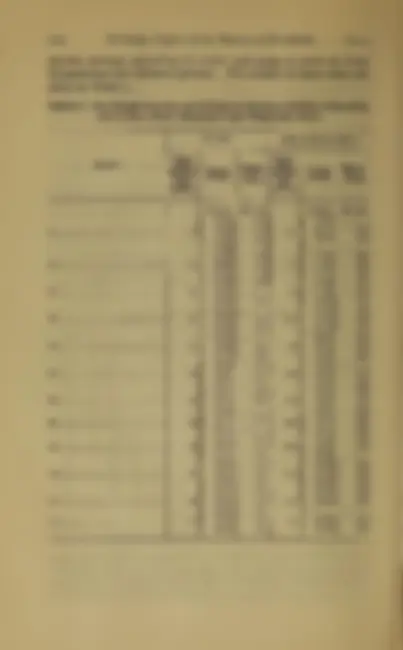

and of Heat-treated^ Aluminum-^ Copper-Magnesium^ Alloys—Continued

Hmnber

CI

01

cs

C

C

C

C

Quenched from 478° C

at 110°

at 20°

11 11 11

Scleroscope

magnifying hammer

Tensile strength

Lbs./in.a 36 870 37 080 36 260

16 830 16 510 16 510

28 020 25 810 25 440

29 300 28 910 30 280

33 220 32 580 31 930

31 050 33 790 31 640

42 350 42 530 42 350

46 400 47 030 48 900 47 650 31 790 30 450 30 070

38 030 37 630 38 430

50 450 48 950 51 740 50 880 38 330 38 730 35 910

Elonga- tion in 2 inches

P.ct.

Quenched from 510° C

at 110°

at 20°

1

Scleroscope

hammer

strength

Lbs./in. 17 38 030 37 220 27 48 120 47 210 16 670

8

Elonga- tion in 2 inches

P.ct.

T5.

Merica, Wallenberg,! Scott (^) J Heat^ Treatment^ of^ Duralumin^277

C4, and^ C9)^ show^ an^ increase^ of^ hardness^ of^ the^ hest-treated^ speci-

mens over that of the annealed samples. The increase of hardness

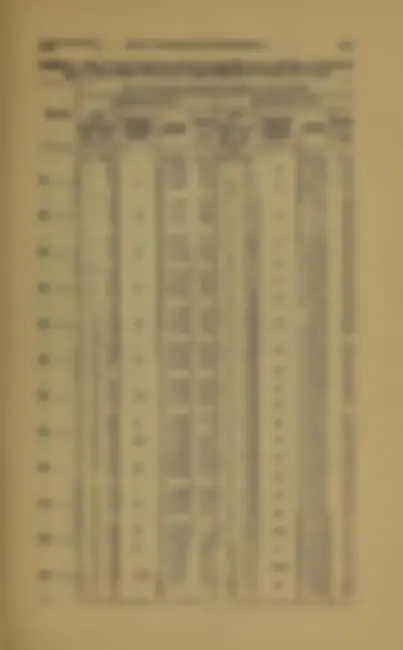

shown in the following table

Number of alloy

Increase of ten- sile strength of heat-treated

alloy

C9 —^4

by quenching from the higher^ temperatures^ (500 to 525° C). This is shown in^ Table^ 3, giving^ further^ data^ on^ two^ alloys,^ C8 and Cii, and^ will^ be shown^ more^ clearly^ below. 121040°— 19 2

278 Scientific^ Papers^ of the^ Bureau^ of Standards^ [Voi. 15

20° C 110° C

Sclero- scope

Ultimate tensile strength

tion in 2 inches

20° (^) C 110° (^) C

Sclero- scope

Ultimate tensile strength

tion in 2 inches

37r (^) C...

7 7 13 13 7 7 13 13 7 7 11 11 [ ^^ 11 8 [ 8 [ 11 11 { 11 I 11

( 1 '' 11 8 [ 8

I ^^ 1 13

11

12

}"

22

....

Lbs./in. 27 260 1 26 220 J^29 1 29 130 J^39 1 40 160 J

f 44 130 1 44 910

J

7 7 13 13 7 7 13 13 7 7 11 11 11 11 8 8

Lbs./in. { 35 900 I 36 550 J^35 1 35 020 J

J

j 50 450 1 48 950 J^51 1 50 880 J^52 1 52 590 J^51 1 50 870 J

478° C

500° (^) C

1 520° C .

525° (^) C

r 48 370 t 47 060

Not only does the hardness increase after heat treatment, but so also does the ductility, as evidenced by the elongation in the tensile test. This is shown in Tables 2 and (^) 3.

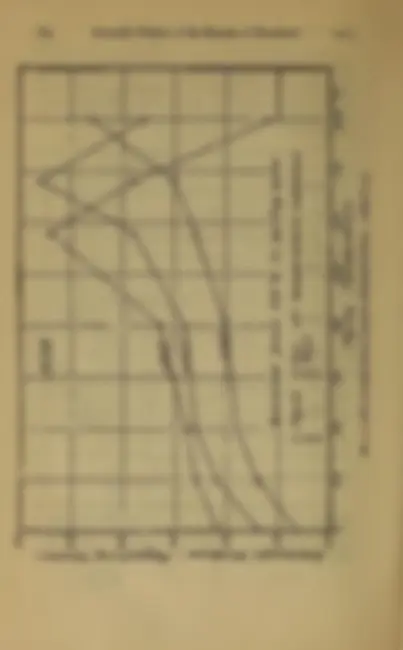

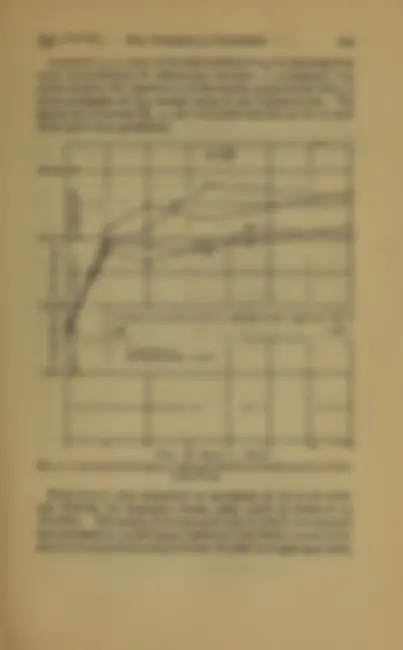

In Fig. I are shown the scleroscope hardness values of Cii quenched in water (20° C) from different temperatures and aged

at room^ temperature^ for^ periods^ of^ time^ from a^ few^ hours^ to^30 days. The form of these aging curves is similar to that shown by Cohn (see notes 3 and 5 on (^) p. 271) ; that is, the hardness increases

after quenching,^ at^ first^ rapidly^ and^ then^ more^ slowly.^ It^ is^ fur-

28o Scientific Papers (^) of the Bureau (^) of Standards' [Vol. IS

ther evident that the maximum hardness attained increases with

the temperatm*e up to approximately 520° C.

The effect of quenching temperature is also shown very nicely

in an experiment of which the results are shown in Fig. 2. Two

strips of 0.087-inch sheet of alloy N34 were used. The strip (^) was

placed in the furnace for heating in such a manner that a nearly

linear temperature gradient^ existed^ between^ the^ two ends,^ as

Ift ^ "O ^ Ifj "^ (^) ^

shown by thermocouples placed along the strip. Upon attaining

the desired range of temperattires, the strip was quenched in boiling water and aged 20 hours at 110°^ C. The scleroscope hardness was then determined along the axis of the strip, and is shown in Fig. 2 as a function of the distance from one end of the sample. The distance may be regarded as a rough temperature

of Duralumin^281

marked on^ the^ curve.^ One^ strip^ was^ quenched^ when^ the^ two

ends were^ at 520 and^ 280°^ C,^ respectively;^ the^ other,^ when^ the

ends were at 490 and 210°^ C, respectively. Beginning at about

a temperatiu'e of about 520° C is reached. Beyond that temper-

with a dark gray oxide coating and generally also with blisters,

marking the temperature of eutectic melting. The effect of heat-

ing to temperatures around 300°^ C is chiefly to anneal the specimen

and to give lower values of the hardness (minimum^ on the curve)

than is given by heating^ at lower^ temperatures.

perature of quenching^ bath and^ of aging^ carried out in the bath.

The samples used were strips of (^) A1-12 quenched from 520° (^) C.

The increase of strength witli time of aging (^) is evident.

Merica, Waltenberg,! ScoU J Heat^ Treatment^ of^ Duralumin^283

A more complete^ picture^ of^ the^ phenomenon^ of^ hardening^ by

aging at different^ temperatures^ is^ obtained^ from^ Figs.^ 3, 4, and^ 5,

based upon^ data^ obtained^ on^ specimens^ of^ N34.^ The^ sclerocsope

values of^ Fig.^3 were^ obtained^ upon^ samples^ quenched^ in^ boiling

water from^ two^ temperatures,^515 and^ 525°^ C,^ and^ aged^ at^ differ-

ent temperatiu-es.^ The^ same^ figures^ are^ replotted^ in^ Fig.^4 in

different form.

Fig. 3. Effect of aging at different temperatures on the^ scleroscope^ hardness^ of samples

perature of aging (^) increases, (2) that the maximum hardness (^) is obtained by aging at temperattu-es above 100° (^) C, and (^) (3) that at aging temperatures above 140° C the hardness eventually drops after reaching its maximum.

284 Scientific Papers (^) of the Bureau (^) of Standards [Vol. (^) IS

'^ifcuudc?^ Bu/Aj/u^£:?/^ -^ S'^^c/^^i:^//^ »^<?:?s^o^^/:?^

286 Scientific Papers (^) of the Bureau (^) of Standards [Voi.is

results. Those samples quenched to 150° C gave practically the

same results as those quenched to 230° C, although there is a

slight improvement in the tensile properties of those quenched to

150° (^) C over those quenched to 100°^ C.

In Table^6 are shown results^ of^ tests^ to^ determine^ the^ effect^ of

aging at room temperature after aging^ at the temperature of the

increase in the strength of the alloy produced by aging at 20°^ C

Merica, Waltenberg, Scott (^) ] Heat^ Treatment^ of^ Duralumin^287

g Q Pi , « , «iO ^g >ao U <J »o .0^ t>k^ m

1 1 Jr. tS| a

n .S

. o

i

)

1

^ ^ KJ {Q 1 S (^) eg : ^ ^

Per

cent 23.5 26.0 21.5 26.0 22.5 (^) 22. 53 • 53 S

•St

3 ^^ ^^ ^^ *^ *^ *

^CO st^ •<1- CO

il

2

I

Is

II

C3\ t«. CO CO CO (^) t^ CO CO CO

CS? to ^ .0 to

OtotOOOiOOO ;o;HvgvgvocMvo^

42

950 43

600 49

300 50

450 49

750 48

(^550) §1111 |S|

(^1) 6"

g

J3 53 2 JQ

o J5 (^53) CO CO

«

II

4§§ ^55?^ i^ 1 Z^ s?^ S

.a

1

Is il g^ S^ {Q^ S ^^ S^ S^ s^ ?5^ s^ J?^ ^^ s

II (^) goo to cd 5^ 2 53 53

to to 10 ;5 S 53 5^ 53 5^

1 —^

45

750 45

025 44

900 44

450 44

550 44

700 47

100 45

950 47

000 47

000 48

250

i3«

::i^ 2 ^ ^ ^ CO CO 0^ CJ^ ? 00 s s

Stott ]^ Heat^ Treatment^ of^ Duralumin^289

5S 55 S ^

irt a> o^ 06

47

600

47

100 50

400 50

750

:? ^

CO CO CO CO a a

n 10 Tl^ CM COCM (^) CM-^ CMCM a

51

450 48

500

a

54

600

a

53

850

S ^

^ (^) :

00 c^

CM CM (^) S s

: 5?

^ ^ « a

«MCM COcq

10

a

CM a

CM CM (^) s s

290 Scientific Papers (^) of the^ Bureau^ of Standards^ \V0L