Study with the several resources on Docsity

Earn points by helping other students or get them with a premium plan

Prepare for your exams

Study with the several resources on Docsity

Earn points to download

Earn points by helping other students or get them with a premium plan

Community

Ask the community for help and clear up your study doubts

Discover the best universities in your country according to Docsity users

Free resources

Download our free guides on studying techniques, anxiety management strategies, and thesis advice from Docsity tutors

Some concept of Turbomachinery Aerodynamics are Axial Flow Compressors, Axial Turbine Design Considerations, Blade Performance, Engine Performance Significantly, Flows Through Axial Compresso. Main points of this lecture are: Blade Design Procedure, Design Method, Indiviual Stage, Ideal Work, Transonic Fan, Fan Design, Rarely Used, Possibility, Carter’S Deviation, Design Point

Typology: Slides

1 / 20

This page cannot be seen from the preview

Don't miss anything!

1

Aerodynamic Design of Axial Compressor

---------------- Blade design Procedure

2 2

-1 (^) w.1r -1^ a,1r

1,r 1,r

1 1,r 1,m m

-1^ 1,r^ w,1r

a,1r

INDIVIUAL STAGE DESIGN METHOD

Absolute Vel

Absolute Angle

Blade Speed

Relative Angle

1,a 1,r 1,r

C V = cos β

2 2,r 2,m 2,m

r U = U. r

2m w,2r w,2m

r C = C. r

w,rm m

C DR = 1 - 2.U.r

Check

Relative Vel

Degree of Reaction, Rx should never be zero anywhere on the rotor blade

or assume a value for

AVDR = C (^) a1. ρ 1 /C (^) a2. ρ 2

-1 w,2r 2,r a,2r

(^) ( )

-1 2,r^ w,2r 2,r a,2r

U - C β = tan C

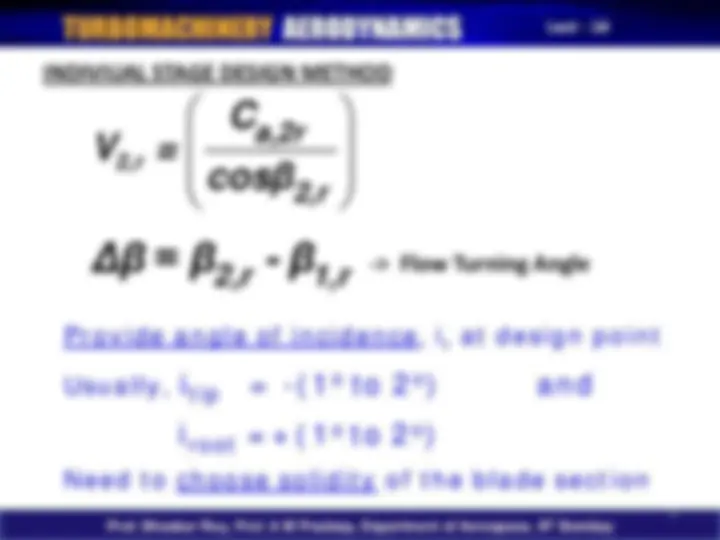

Δβ = β 2,r (^) - β 1,r

≈ 1 0.

V 2 <V 1 →

V 2 =V 1 →

V 2 >V 1 →

Generally accepted

Rarely Used

transonic fan design – possibility

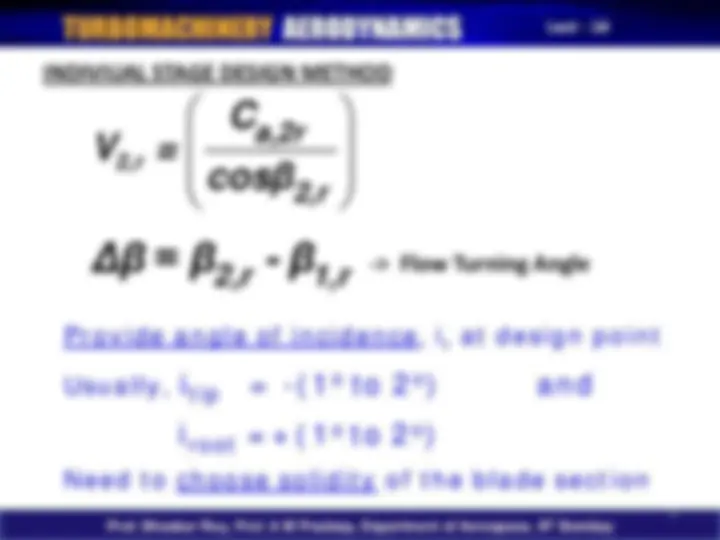

INDIVIUAL STAGE DESIGN METHOD

2,r

C V = cos β

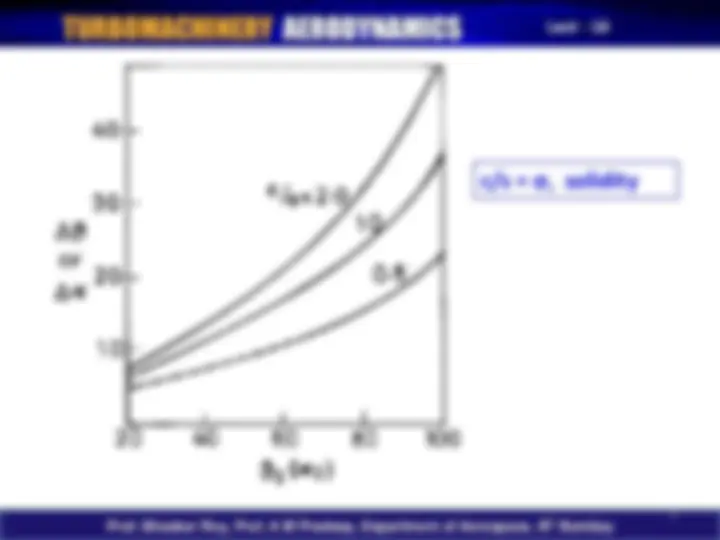

Δβ = β 2,r (^) - β 1,r -> Flow Turning Angle

Provide angle of incidence, ir at design point

Need to choose solidity of the blade section

M (^) u = U/a

INDIVIUAL STAGE DESIGN METHOD

r• 2,r^ ′ 2,r r

s δ = β - β = m .θ. c

(Carter’s deviation – valid at design point)

At any radius

Deviation,

18

depending on the law of profile and its values change from 0 to 0.2 at the root to 0.8 to 1 at the tip.

( 1 ) D

1 c

cos Δ + - cos = 180 × c π (^) h s

c^ β^ β^ β θ

These three are connected by

19

Transonic Compressor Basic Characteristics

3-D Blade Shapes

Follow similar step-by-step procedure for STATOR blade design by building up airfoil sections from hub to tip to match with the ROTOR blade design.

Stage design is completed after the rotor-matched stator design is completed.

Modern Blade designers have started using 3-D airfoils which are set on cylindrical coordinates, even as they are radially stacked.